At the very start of our conversation, Jiří Svoboda—the company’s director and a long-time member since the days of the Aeronautical Research and Test Institute (VZLÚ)—offered a vivid look back at SPEEL’s earliest beginnings.

“There used to be a dedicated aviation diagnostics division at VZLÚ,” he recalled. “I joined in 1982 and worked on a tape-based crash recorder, which we managed to develop here. But then 1989 came, the Velvet Revolution changed a lot, and the institute’s finances gradually worsened. People were leaving, and we were effectively forced by the economic situation to establish our own company. That’s when we made the leap to recorders using solid-state memory, secured our first major contract with Aero Vodochody, and kept advancing from there.”

Having set the historical scene, Svoboda stayed to listen as his colleagues took over, fleshing out just how this once-modest spinoff rose to become an influential—yet astonishingly discreet—player in the global avionics arena.

A Quiet Hero with Global Reach

Imagine sitting in an aircraft cockpit, where each ticking second can tip the balance between success and failure. In these high-stakes moments, pilots rely on technology that never falters. And it’s precisely there—amid the roar of engines and pounding adrenaline—that the strengths of a small Prague-based team named SPEEL PRAHA shine brightest.

In a field dominated by colossal multinational corporations and vast budgets, here’s a Czech company that steps in exactly where the big players might shrug and walk away.

What’s behind their success? We spoke with Petr Vidiečan (R&D Director) and Pavel Valina (Sales Manager), who radiate enthusiasm for SPEEL’s journey. They credit determination, meticulous diligence, and innovative thinking—traits inherited from their VZLÚ days. But SPEEL also adds incredibly fast delivery times and a personal approach absent in many large corporations. Their HUDs with dual-color backlighting are lauded for superior night-vision compatibility, while their CARE crash recorders keep older aircraft flying long after most manufacturers would have deemed them obsolete.

On a practical level, if a Mirage in Pakistan or a Mi-17 in Azerbaijan encounters an issue, local crews know they can simply call SPEEL in Prague, jump on WhatsApp for guidance, and—if needed—have a technician on a plane in short order. No convoluted management ladder, no “we can’t do that.” Instead of a thicket of corporate red tape requiring a hundred signatures, one conversation is enough for SPEEL to act.

It’s precisely this kind of responsiveness that attracts not just military air forces but also aircraft and helicopter manufacturers—and even Prague’s metro, where multiple generations of SPEEL tachographs have been in use for years.

How do they keep it cost-effective? The key is surprisingly simple: do only what really matters. They don’t bloat overheads or throw in flashy “wow” features nobody needs. The result is a solution on par with global standards, yet imbued with a human touch too often missing in aviation.

In many ways, SPEEL PRAHA is a quiet hero, driven by the satisfaction of pilots and technicians rather than flashy marketing. Once you hear their story, you realize top-tier avionics needn’t come with an astronomical price tag—and that even a small Czech firm can shape modern aviation. By the time a larger competitor has merely convened its first approval meeting, SPEEL might already be packing a fully operational system for shipment—proving true innovation thrives where people respond swiftly, pragmatically, and with genuine passion.

What do you consider the key milestones that established SPEEL’s reputation in the aviation industry?

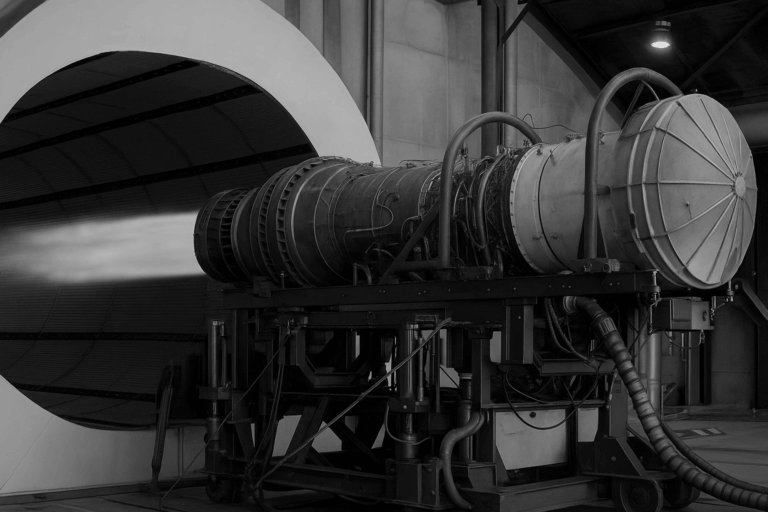

SPEEL’s reputation in the aviation industry was built on several key milestones. The first was the development of the FDR-39 crash recorder for the L-39, successfully exported to Thailand, proving that a small Prague-based firm could reliably supply the international market. A major turning point followed with the L-159, for which we developed the AMOS monitoring system, providing real-time aircraft status data to pilots and ground crews while integrating with the MIL-STD-1553 avionics bus, paving the way for collaborations with Rockwell and Boeing.

Our next major success was the CARE (Crash Protected Recording Equipment) system, first deployed in the Pakistani Air Force on F-7 jets (a MiG-21 license), later expanding to Mirage III/5, C-130 Hercules, the French DA-20, and China’s Y-12, as well as Mi-series helicopters in Azerbaijan and Georgia through partnerships with repair facilities in Malesice and Helisota—resulting in over 200 systems in operation in Pakistan alone.

Another milestone came with the PDU-39 (HUD) for L-39 modernizations in Kazakhstan, Nigeria, and Ethiopia, followed by the more advanced PDU-159 for L-159 upgrades, which is fully digital, night-vision compatible, equipped with dual (green-red) backlighting, and capable of displaying raster video from FLIR. Today, these cutting-edge displays are also installed on the L-39NG, reinforcing SPEEL’s role in modern aircraft avionics.

What are your next steps? You mentioned waveguide optics for HUDs.

Waveguide could be a revolution for smaller aircraft. A traditional HUD is fairly large and weighs 8–11 kg—significant on a basic turboprop trainer where every kilogram counts. Waveguide would drastically reduce the amount of glass and lenses. The display would be lighter and more compact, letting us offer a fully digital HUD for smaller manufacturers.

Speaking of MRO (Maintenance, Repair, and Overhaul), does that mean you see more expansion opportunities beyond the Czech Republic?

Absolutely. LOM Praha is a key partner, as are Helisota and ASU Baltija in the Baltics. Through them, we reach customers who want to upgrade older Mi-17s or transport aircraft with a new recorder, HUD, or health-monitoring systems—often in small batches, which big corporations won’t do. We’re also in talks with other manufacturers, such as Aircraft Industries (L 410), ENAER, Grob Aircraft, and so on.

What do you personally enjoy most about this work?

Definitely the variety. We’re still a small team with no ten-level management hierarchy, so you get to experience the entire process—from conceptualizing a new module to conducting flight tests and supporting pilots in the field. In a large corporation, you might only see one slice of the puzzle, but here, you see how it all integrates into a real aircraft, helicopter, or even a metro car.

So would you say SPEEL is a hidden gem of Central Europe?

That’s what customers tell us. (laughs) We’re not loud in marketing, but we’ve built a global track record—Pakistan, Nigeria, Kazakhstan, Egypt, Azerbaijan, Rwanda… and here at home, Omnipol, LOM Praha, and Aero Vodochody, where we supply over fifteen different electronics components for the L-39NG. We don’t have a huge bureaucracy, which lets us respond quickly, and that’s appreciated. We keep our pricing “cost-effective” without sacrificing quality. We’re a bit different from the big corporations—and evidently, many people value that.

(The interview ends, but SPEEL PRAHA’s story continues in countless cockpits around the world. Drawing on their VZLÚ heritage of precise engineering and innovation, they thrive on immediate problem-solving and strong communication with pilots and technicians. Whether it’s a digital HUD, a crash recorder, or the sophisticated PANDA software, one thing is certain: with SPEEL, you pay a fair price, get top-notch technology, and enjoy a remarkably personal touch.)

Interviewed by: Kateřina Urbanová

Photo Credit: Speel Praha, Kateřina Urbanová