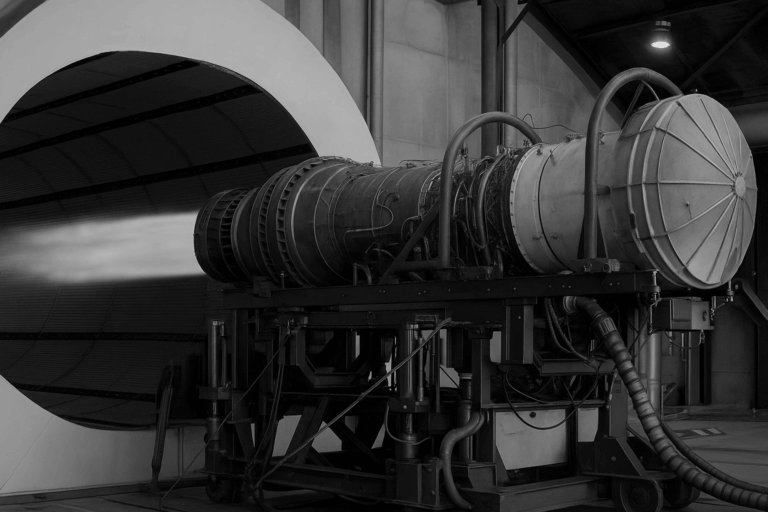

Which types of radiographic films are best for aerospace inspection? The short answer is it depends on the part, the defect you need to find and the inspection requirements for that aircraft. Radiographic film is still the go-to for many flight-critical checks because of its fine detail and proven track record.

When choosing a film, though, it’s important to pick the right type and vendor to ensure the film matches the parts, materials and inspection requirements.

Benefits of Radiographic Films for Aerospace Inspection

Radiographic films are still important in aerospace inspection due to the following reasons:

- High spatial resolution: Film can show small defects and fine detail that are hard to capture with some digital panels.

- Strong contrast for small indications: The right film emulsion makes subtle density differences more visible, which helps find small cracks, inclusions or porosity.

- Proven and widely accepted: Film-based radiography is a known quantity in many aircraft maintenance requirements, so it is often the safe choice for flight-critical parts.

- Physical, hard-copy record: A properly processed film provides a tangible image that can be archived and reviewed without needing a digital chain of custody.

- Flexible material and thickness options: Different film speed classes and emulsions let you match the film to part material, section thickness and the defect size you are targeting.

Which Types of Radiographic Films Are Best for Aerospace Inspection?

Below are the common types of radiographic films you will see in aerospace shops. Each has trade-offs between detail, contrast and speed.

1. Fine-Grain, High-Resolution

These are very fine emulsion grains designed for the sharpest images. They are useful for flight-critical, thin sections, investment castings and anywhere you must spot small cracks or inclusions. They work best for detectability but usually require longer exposure and strict process control.

2. High-Contrast

High-contrast emulsions are tuned to increase the contrast between small density differences. They are suitable for weld inspections, hairline cracks, and small indications. However, processing must be consistent for narrower exposure latitudes.

3. Balanced-Latitude

This type compromises between contrast and exposure latitude. It works best for mixed workloads where reliable results across different materials and thicknesses are needed. It can be more forgiving during processing and offer easier repeatability, but it will not match the finest detail of the best fine-grain films.

4. High-Speed

This film is emulsion-engineered to give usable images with shorter exposures. High-speed film works for large castings or wherever reduced exposure time is important. One downside is that it offers lower spatial resolution, so it may miss the smallest indications unless the person using it compensates with technique and magnification.

Top Vendors for Radiographic Films for Aerospace Inspections

| Vendor | Key Product(s) | Notable Features | Support & Services | U.S. Availability |

| FUJIFILM | Radiographic Film | Consistent grain, high contrast, repeatable sensitometry, ADR for workflow | U.S. service, hands-on support, software | Yes |

| Waygate Technologies | STRUCTURIX Film Systems | High image quality, fine grain, SAL protective coating, multiple packaging types | Chemicals, processors, compliance support | Yes |

| Carestream | INDUSTREX Film | Fine grain, strong contrast, various speed classes, multiple film types | Film selection support, processing support | Yes |

| Kodak | 7125 Lineup | Durable, static/heat/artifact-resistant, strong contrast, easy processing | Chemistry, processing, distributor network | Yes |

The following trusted vendors supply radiographic films made for aerospace inspections.

FUJIFILM

FUJIFILM North America Corporation is a long-standing leader in imaging and a top choice for radiographic films for aerospace companies. Its radiographic film remains one of the most established products, prized for consistent grain, high contrast and repeatable sensitometry that helps non-destructive testing (NDT) technicians find small defects in flight-critical components.

Beyond its products, FUJIFILM provides U.S. service coverage and hands-on customer support, plus in-house software development for Industry 4.0 efficiencies. Its viewing and workflow roadmap includes Assisted Defect Recognition (ADR) to speed and standardize reviews — a useful bridge for shops that need film today but want an easier path to computed radiography (CR) and direct radiography (DR) later.

Waygate Technologies

Waygate Technologies (Baker Hughes) is a full-spectrum NDT supplier that supports traditional film workflows and digital radiography, so shops can find tools and retrofit options in one place. It makes industrial X-ray film systems with its STRUCTURIX line. These films are made for high image quality and fine grain, with formulations tuned for aerospace tasks like weld and casting inspection, composite checks and more. They also feature a protective coating from their Split Antistress Layer (SAL) technology, which helps with handling and storage.

The STRUCTURIX films come in multiple packaging types and sizes, and the company supplies the chemicals and processors needed to get repeatable results. Waygate Technologies’ film systems also meet common international standards like EN ISO 11699-1 and ASTM E1815, so the vendor ensures teams stay compliant with aircraft maintenance requirements.

Carestream

Carestream is a large provider of radiographic film for aerospace inspections. The brand offers film emulsions and speed classes and helps chemical and processor shops get consistent, repeatable results.

Its INDUSTREX line is a well-known choice for the aerospace industry. These films are made for high image quality with fine grain, strong contrast and good sensitivity. Carestream supports shops with various film types to choose the right balance of sharpness, speed and durability for the part and defect size. Some options include the slow-speed M100 for the sharpest detail and the ultra-fine DR50 for high-energy applications.

Kodak

Kodak is a solid option when you need durable, high-quality radiographic films for aerospace inspections. For example, the 7125 lineup gives clear detail and strong contrast for aircraft parts. Kodak’s films are also static-, heat- and artifact-resistant and meet industry test standards for strict aircraft maintenance.

Kodak also supplies the chemistry and processing support shops need and works with distributors to make products available in the U.S. That makes Kodak a top pick for teams that want rugged, easy-to-process film with good tonal quality.

Matching Film to Your Aerospace Inspection Program

Radiographic films for aerospace inspections continue to deliver clear, high-detail images that help find tiny defects in aircraft parts. There are many trusted suppliers and film families to choose from, so the right vendor depends on your aircraft maintenance requirements. To balance image quality and processing, choose the film and supplier that best match the inspection tasks and validate with a demo to ensure the workflow meets your requirements.

By: Megan Vitanza